Anodized Aluminum Plate

Short description:

- TYPE: Extruded Aluminium Bar

- GRADE : 1060,1100,5052,6061,6063,6082

- COLOR : According to customer’s requirement

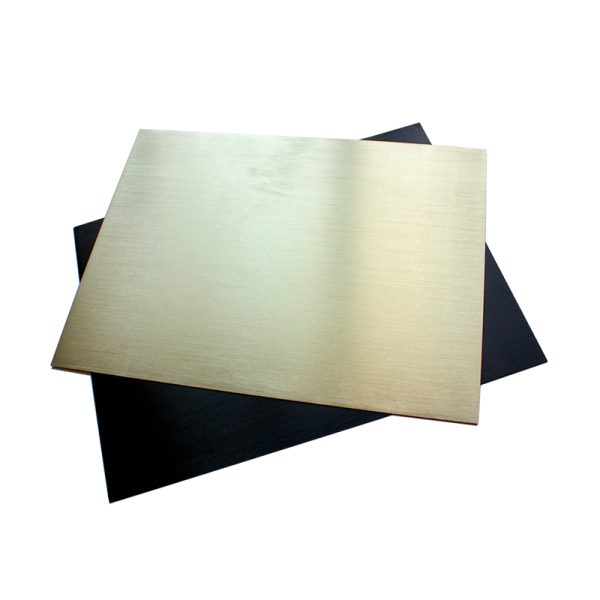

- EFFECT: Brushed, Sandblasting, Matte,Hard anodizing

- MOQ: 30 KGS

Product description:

According to the specific needs of customers, we will make corresponding solution.

Advantages of anodized aluminum plate

(1) Good processability: anodized aluminum plate decorative strong, moderate hardness, easy bending molding, continuous high-speed stamping, convenient direct processing into products, without complex surface treatment, greatly reduce product production cycle and reduce product production costs.

(2) Good weather resistance: the anodized aluminum plate of standard thickness oxide film (3μm) is used indoors for a long time without discoloration, corrosion, oxidation and rust. The anodized aluminum plate with thickened oxide film (10μm) can be used outdoors and does not change color when exposed to sunlight for a long time.

(3) Strong metal feeling: the anodized aluminum plate surface hardness, up to gem grade, good scratch resistance, surface without paint cover, retain the metal color of aluminum plate, highlighting the modern metal feeling, improve product grade and added value.

(4) High fire resistance: pure metal products, surface without paint and any chemical substances, 600 degrees high temperature does not burn, does not produce toxic gas, meet the requirements of fire protection and environmental protection.

(5) Strong anti-fouling: no handprints, there will be stains, easy to clean, no corrosion spots.

(6) Strong applicability: wide use, suitable for metal aluminum ceiling, curtain wall aluminum panel, aluminum plastic panel, fireproof board, honeycomb aluminum panel, aluminum veneer, electrical panel, cabinet panel, furniture panel, etc.

| PLACE OF ORIGIN | China |

|---|---|

| STANDARD | GB/T(default),ASTM,AMS,EN |

| MATERIAL CERTIFICATES | Material test report, and other certificates |

| SAMPLE | Support small sample (Chargeable) |

| PROCESSING SERVICE | Cutting, bending, CNC, anodizing, etc. |

| MOQ | Small MOQ with ready stock,even a piece. |

| LOGISTICS MODE | Express, by Land,by Air,by sea |

| SHIPPING PORT | Shanghai(default) |

| PAYMENT OPTIONS | TT, PayPal, L/C at sight, Pay on Alibaba |

| PACKAGING | Pallet(default), Wooden box(Chargeable) |

| LEAD TIME | 2-7 days for ready stock.Or mutual agreement |

| CUSTOMIZATION | Can be customized according to customer’s requirement |

| ABOUT PRICE | Fluctuate with aluminum prices & USD exchange rate |

About Anodized Aluminum Plate:

Anodized aluminum plate refers to a type of aluminum plate that has been subjected to an electrolytic process to create a thin, protective layer of oxide on the surface. This layer of oxide improves the corrosion resistance, wear resistance, and appearance of the aluminum plate. Anodized aluminum plates are commonly used in architectural applications, such as building facades, as well as in automotive, aerospace, and electronic components. The anodizing process can produce a variety of colors, including silver, bronze, gold, black, and others, by using different electrolytes and processing parameters. Anodized aluminum plates also offer the advantages of being lightweight, strong, and recyclable. The thickness of the anodized layer can vary depending on the application, with thicker layers providing greater durability and resistance to wear and abrasion. Overall, anodized aluminum plates offer a cost-effective and high-performance solution for a wide range of industrial and commercial applications.