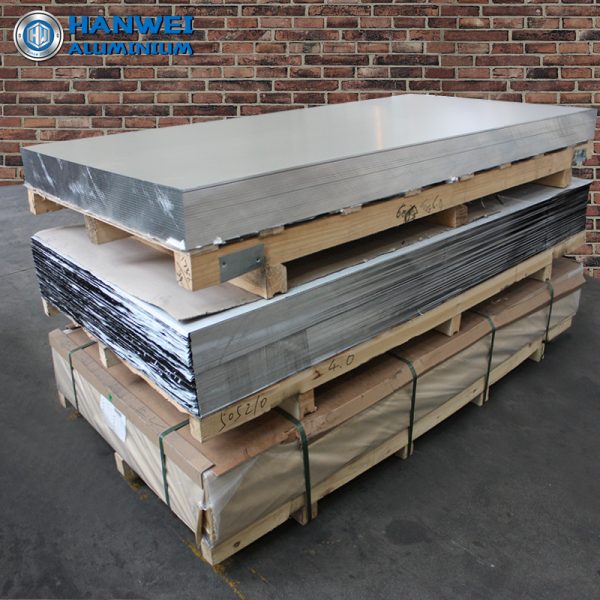

5056 Aluminum Sheet Plate

Short description:

- TEMPER: H112

- THICKNESS: 8-50mm (ready stock)

- WIDTH: 1250-1500mm ; LENGTH: 2500-3000mm

- CUTTING: Can be cut to size

- OTHERS: Material traceability, Mass-stock,Fast shippment

Product description:

Chemical composition of 5056 aluminum alloy

- Aluminum (Al): balance

- Silicon (Si): 0.3% max

- Ferrum (Fe): 0.4% max

- Copper (Cu): 0.1% max

- Manganese (Mn): 0.05-0.2%

- Magnesium (Mg): 4.5-5.6%

- Chromium (Cr): 0.05-0.2%

- Zinc (Zn): 0.1% max

- Other elements: Each 0.05% max, Total 0.15% max

Typical mechanical properties of 5056 H112 aluminum

- Tensile strength: 270 MPa

- Yield strength: 200 MPa

- Elongation: 12%

- Hardness (Brinell): 80 HB

(The values are typical or min values,for reference only.)

| PLACE OF ORIGIN | China |

|---|---|

| STANDARD | GB/T(default),ASTM,AMS,EN |

| MATERIAL CERTIFICATES | Material test report, and other certificates |

| SAMPLE | Support small sample (Chargeable) |

| PROCESSING SERVICE | Cutting, bending, CNC, anodizing, etc. |

| MOQ | Small MOQ with ready stock,even a piece. |

| LOGISTICS MODE | Express, by Land,by Air,by sea |

| SHIPPING PORT | Shanghai(default) |

| PAYMENT OPTIONS | TT, PayPal, L/C at sight, Pay on Alibaba |

| PACKAGING | Pallet(default), Wooden box(Chargeable) |

| LEAD TIME | 2-7 days for ready stock.Or mutual agreement |

| CUSTOMIZATION | Can be customized according to customer’s requirement |

| ABOUT PRICE | Fluctuate with aluminum prices & USD exchange rate |

About 5056 Aluminum Sheet Plate:

5056 aluminum is a high-strength alloy with excellent corrosion resistance, commonly used in marine and aerospace applications. Its composition includes magnesium, manganese, chromium, and zinc, which contribute to its strength and durability. It has good weldability and machinability, making it a popular choice for structural components and panels in the aerospace industry. Additionally, 5056 aluminum has good forming and bending properties, making it suitable for use in shipbuilding and other applications where a combination of strength and corrosion resistance is required. The alloy is available in various forms including sheet, plate, and extruded shapes, and can be finished with a range of surface treatments such as anodizing or painting to enhance its corrosion resistance and aesthetic appeal.